What is ABS Filament

What is ABS Filament? A Comprehensive Guide to 3D Printing with ABS In the realm of 3D printing, filament

What is PLA Filament?

What is PLA Filament? PLA filament is one of the most popular and widely used materials in 3D printing. Whether

What is 3D Printing

What is 3D Printing Are you curious about the transformative potential of 3D printing? This cutting-edge technology is revolutionizing manufacturing

Castable Resins for 3D Printers

Castable Resins for 3D Printers 3D printing can help you create highly complex structures, but it’s not always the best

Water-Washable Resin 3D Printer

Water-Washable Resin 3D Printer Are you looking for convenience and cost savings in the world of 3D printing? Then a

3D Printing in the Automotive Sector: Prototypes and Replacement Parts from the Printer

3D Printing in the Automotive Sector: Prototypes and Replacement Parts from the Printer The 3D printing technology is revolutionizing the

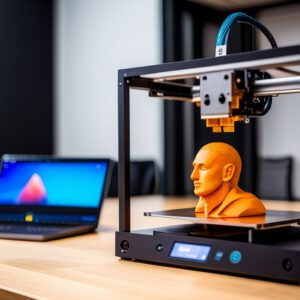

What is 3D Printing?

3D printing, also known as additive manufacturing, is the process of creating three-dimensional solid objects from a digital file. This innovative technology builds objects layer by layer, fusing each layer to the one below until the final product is complete. Although 3D printing has existed for decades, it has only recently become affordable and widely accessible to consumers. This technology is transforming industries such as healthcare, architecture, and fashion by enabling new possibilities in design and manufacturing.

Defining 3D Printing

3D printing is a form of additive manufacturing where material is deposited layer by layer to construct three-dimensional objects. Unlike traditional manufacturing, which typically involves removing material to achieve the desired shape, 3D printing adds material, allowing for intricate and precise creations. Common materials used in 3D printing include polymers and metals, which are extruded through a nozzle onto a flat surface. This capability to produce finely detailed objects is particularly beneficial in industries like medicine and engineering, where precision is critical. The ability to customize designs and produce complex structures without extensive resources has revolutionized the manufacturing process.

How Does 3D Printing Work?

3D printing, or additive manufacturing, transforms digital models into physical objects by depositing materials such as plastic or metal in successive layers. Over the past decade, advancements in 3D printing technology have made it increasingly accessible to everyday consumers. Despite the variety of 3D printers available, they all follow a similar process: converting digital information into physical objects with specific shapes and features. Today, 3D printers are used for a wide range of applications, from creating prosthetics and medical shields to producing custom-designed chocolate confections.

Benefits of 3D Printing

Since its inception, 3D printing has rapidly advanced, offering numerous benefits across multiple industries. Key advantages include cost efficiency, speed, scalability, flexibility, customization, and sustainability. By utilizing digital files instead of traditional manufacturing methods like casting or machining, 3D printing significantly reduces production costs while enabling rapid prototyping and scalable manufacturing. The technology also allows for the creation of complex shapes that are difficult or impossible to achieve with conventional methods, providing more customization options and reducing material waste commonly associated with traditional manufacturing processes. These factors make 3D printing one of the most innovative and efficient manufacturing technologies available today.

Common Applications of 3D Printing Technology

3D printing technology is revolutionizing a wide range of industries, from aerospace and automotive to medical fields. In aerospace, engineers can manufacture complex multipart components in a single step, saving time and resources. In the medical industry, 3D printing is used to reconstruct bones and skin, create personalized prosthetics, and produce medical devices like syringes. As research and development continue, new applications for 3D printing are being discovered, further enhancing efficiency and cost-effectiveness across various sectors.

The Future of 3D Printing

The future of 3D printing is filled with exciting possibilities. This technology has the potential to reduce waste, create larger and more complex structures, and provide customized solutions across industries from defense to medicine. With advances in material science and computing power, 3D printers can now produce intricate objects without relying on traditional materials. Emerging technologies are also enabling faster additive manufacturing processes with improved strength-to-weight ratios. As 3D printing becomes more affordable and accessible, its applications will continue to expand, making it a critical tool in the future of manufacturing and design.

Since its development in the 1980s, 3D printing technology has evolved significantly. Today, it is used for everything from prototyping to producing end-use parts, offering lower production costs, higher efficiency, and greater customization. As this technology continues to advance, even more innovative applications for 3D printing are likely to emerge, further transforming industries and driving the future of manufacturing.